Imagen 1 de 6

Galería

Imagen 1 de 6

¿Quieres vender uno?

Kanban For The Shopfloor Textbook Shopfloor Series

USD9,50

Aproximadamente8,17 EUR

Estado:

2 disponibles

Oops! Looks like we're having trouble connecting to our server.

Refresh your browser window to try again.

Envío:

Gratis USPS Media MailTM.

Ubicado en: Cary, North Carolina, Estados Unidos

Entrega:

Entrega prevista entre el jue. 30 oct. y el mar. 4 nov. a 94104

Devoluciones:

30 días para devoluciones. El comprador paga el envío de la devolución..

Pagos:

Compra con confianza

El vendedor asume toda la responsabilidad de este anuncio.

N.º de artículo de eBay:166293892453

Última actualización el 09 feb 2024 14:47:12 H.EspVer todas las actualizacionesVer todas las actualizaciones

Características del artículo

- Estado

- Subject Area

- Manufacturing Engineering, Organizational Development

- Personalized

- No

- Subject

- Organizational Development, Manufacturer Excellence, Operattion Excellence, Business

- ISBN

- 9781563272691

Acerca de este producto

Product Identifiers

Publisher

Productivity Press

ISBN-10

1563272695

ISBN-13

9781563272691

eBay Product ID (ePID)

2238173

Product Key Features

Number of Pages

120 Pages

Publication Name

Kanban for the Shopfloor

Language

English

Publication Year

2002

Subject

Industrial Engineering, Purchasing & Buying, Production & Operations Management, Quality Control

Type

Textbook

Subject Area

Technology & Engineering, Business & Economics

Series

The Shopfloor Ser.

Format

Trade Paperback

Dimensions

Item Height

0.2 in

Item Weight

11.2 Oz

Item Length

10 in

Item Width

7.1 in

Additional Product Features

Intended Audience

Scholarly & Professional

LCCN

2001-007647

Illustrated

Yes

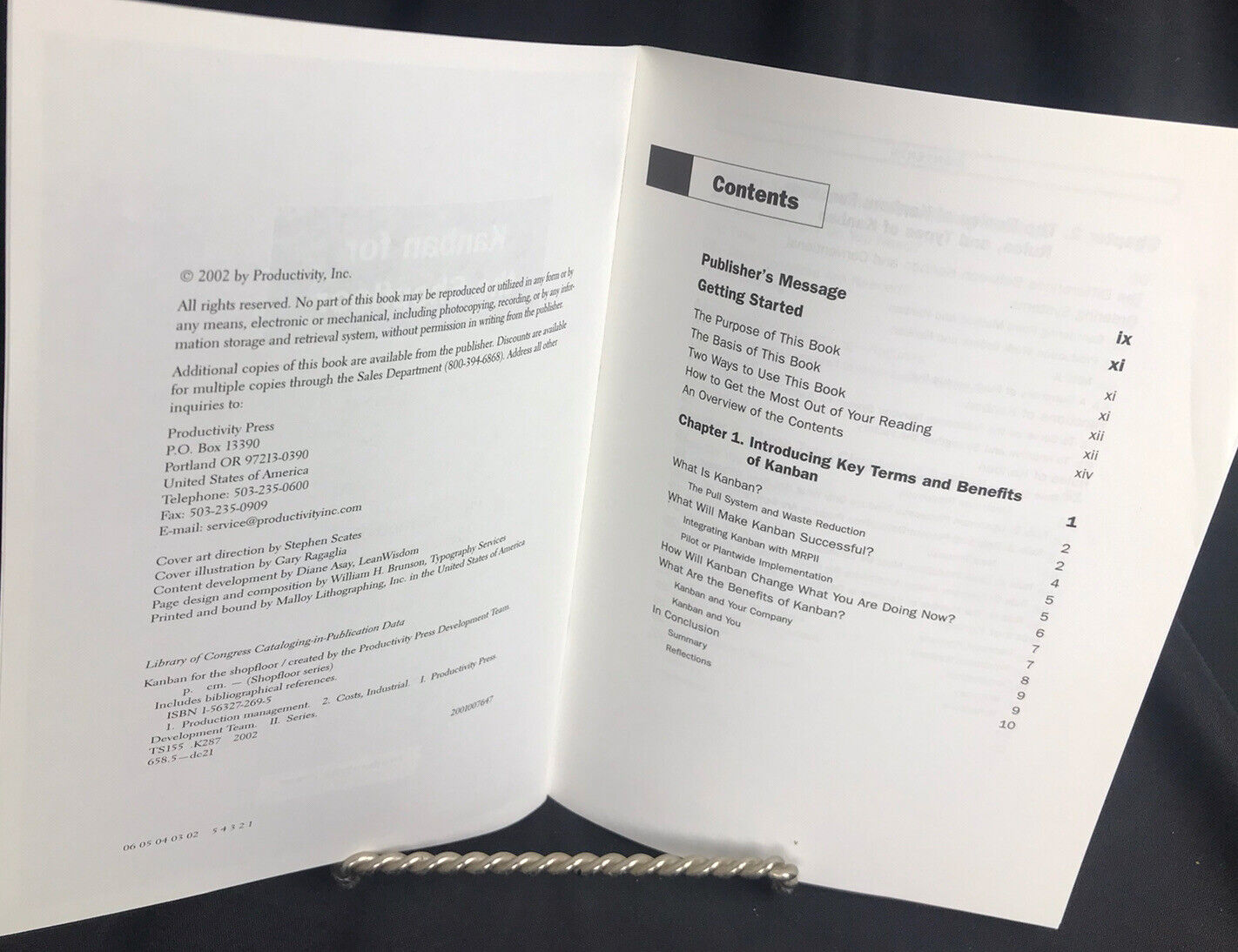

Table Of Content

Publisher's Message Getting Started Chapter 1: Introducing Key Terms and Benefits of Kanban Chapter 2: The Basics of Kanban: Functions, Rules, and Types of Kanban Chapter 3: Phase One: Scheduling Kanban Chapter 4: Phase Two: Circulating Kanban Chapter 5: Phase Three: Improving with Kanban Chapter 6: Reflections and Conclusions

Synopsis

Kanban is the name given to the inventory control card used in a pull system. The primary benefit of kanban is to reduce overproduction, the worst of the seven deadly wastes . A true kanban system produces exactly what is ordered, when it is ordered, and in the quantities ordered. It is essentially a dynamic work order that moves with the material. Each kanban identifies the part or subassembly unit and indicates where each one came from and where each is going. Used this way, kanban acts as a system of information that integrates your plant, connects all processes one to another, and connects the entire value stream to customer demand. Kanban for the Shopfloor provides a working manual for those seeking to implement this method of production control in any operation. It defines the various terms and methods employed in kanbans, and illustrates how when adhered to, kanban is an element of continuous improvement that ultimately leads to the ideal of one-piece flow." In addition to reducing the waste of overproduction, kanban will help your company increase flexibility to respond to customer demand, coordinate production of small lots and wide product variety, and simplify the procurement process. About the Shopfloor Series : Put proven improvement tools in the hands of your entire workforce Progressive shopfloor improvement techniques are imperative for manufacturers who want to stay competitive and to achieve world class excellence. And it's the comprehensive education of all shopfloor workers that ensures full participation and success when implementing new programs. The Shopfloor Series books make practical information accessible to everyone by presenting major concepts and tools in simple, clear language and at a reading level that has been adjusted for operators by skilled instructional designers. One main idea is presented every two to four pages so that the book can be picked up and put down easily. Each chapter begins with an overview and ends with a summary section. Helpful illustrations are used throughout. Other topics in the Shopfloor Series : Kanban, 5S, Quick Changeover, Mistake-Proofing, Just-in-Time, TPM, Cellular Manufacturing, Kanban is the name given to the inventory control card used in a pull system. The primary benefit of kanban is to reduce overproduction, the worst of the seven deadly wastes . A true kanban system produces exactly what is ordered, when it is ordered, and in the quantities ordered. It is essentially a dynamic work order that moves with the material. Each kanban identifies the part or subassembly unit and indicates where each one came from and where each is going. Used this way, kanban acts as a system of information that integrates your plant, connects all processes one to another, and connects the entire value stream to customer demand. Kanban for the Shopfloor provides a working manual for those seeking to implement this method of production control in any operation. It defines the various terms and methods employed in kanbans, and illustrates how when adhered to, kanban is an element of continuous improvement that ultimately leads to the ideal of one-piece flow." In addition to reducing the waste of overproduction, kanban will help your company increase flexibility to respond to customer demand, coordinate production of small lots and wide product variety, and simplify the procurement process. About the Shopfloor Series : Put proven improvement tools in the hands of your entire workforce! Progressive shopfloor improvement techniques are imperative for manufacturers who want to stay competitive and to achieve world class excellence. And it's the comprehensive education of all shopfloor workers that ensures full participation and success when implementing new programs. The Shopfloor Series books make practical information accessible to everyone by presenting major concepts and tools in simple, clear language and at a reading level that has been adjusted for operators by skilled instructional designers. One main idea is presented every two to four pages so that the book can be picked up and put down easily. Each chapter begins with an overview and ends with a summary section. Helpful illustrations are used throughout. Other topics in the Shopfloor Series : Kanban, 5S, Quick Changeover, Mistake-Proofing, Just-in-Time, TPM, Cellular Manufacturing

LC Classification Number

TS155.K287 2002

Descripción del artículo del vendedor

Acerca de este vendedor

nautilus one fifty

100% de votos positivos•1,2 mil artículos vendidos

Registrado como vendedor particularPor tanto, no se aplican los derechos de los consumidores derivados de las leyes de protección de los consumidores de la UE. La Garantía al cliente de eBay sigue aplicando a la mayoría de compras. Más informaciónMás información

Categorías populares de esta tienda

Votos de vendedor (466)

- w***0 (5186)- Votos emitidos por el comprador.Últimos 6 mesesCompra verificadaItem as described,well packed,shipped promptly…great ebayer!

- 3***e (126)- Votos emitidos por el comprador.Últimos 6 mesesCompra verificadaItem was in very good condition and showed up as described and pictured. Got it for a great price - Nice easy transaction. Thank you! A++++The Root Cause Analysis Handbook: A Simplified Approach to Identifying, Correcti (#166316336200)

- 0***- (501)- Votos emitidos por el comprador.Últimos 6 mesesCompra verificadaGood item and price. Well packaged. Fast delivery. Thanks.Making the Numbers Count : The Management Accountant As Change Agent - Maskell (#166053222145)